How we process our pepper

The pepper production process doesn’t stop at the farm, we haul all our pepper to Phnom Penh in our truck for sorting and sometimes drying it in the sun in our garden.

Drying & Sorting

All our pepper is sun dried in the natural way, it is laid out on bamboo mats in the direct sun for three to four days. During this time the pepper needs to be turned and moved around every few hours to ensure it is drying nice and evenly for the perfect final product.

As the pepper dries, it is also sorted to remove bits of leaves and sticks that you don’t want in the final product. Any undersized, immature or broken peppercorns are also sorted for using in lower grade pepper, you will notice that our Kampot peppercorns are significantly larger than the average generic branded peppercorns on shop shelves. This ensures only the best peppercorns make the cut into our premium pepper products.

Once it is finally dry, the pepper is given a final sorting by hand – each peppercorn is scruntinised and given a quality check before being added to the final yield. These controls follow the traditional methods where the emphasis was on the quality of the pepper produced, and not the quantity. We maintain standards through the current high demand and you’ll never find any lower quality pepper in our Kampot pepper.

Sterilising the pepper

Once sorted, it’s off to be sterilised in our special oven that kills any bacteria and helps maintain freshness by preventing mould and pests getting into the pepper. Our pepper processing areas are kept immaculately clean. Any contact with the pepper once it is steralised is closely controlled so as to not contaminate the pepper with any dirt or nasty things.

Measuring It Out

Each package of pepper is carefully weighed out into the vacuum bags ready to be placed on the machine. This is our small production line, with one person filling the bags which are passed along to another that weighs and makes small adjustments until the weight is correct. Some of our packaging is packed full of pepper – so if it is not weighed carefully it won’t even fit in the box.

PACKAGING OUR PEPPER

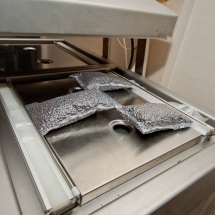

When the vacuum bags are ready, we go over to the vacuum packaging machines. Vacuum packaging is where the product is placed in a special thick plastic bag and then connected to a machine which sucks the air out of the bag and seals the pepper completely away from the environment – which enables you to store and transport the pepper in complete confidence and it typically lasts for years if taken care of.